Carbide Round Saw Cutter

Basic Info

Model No.: Many Types

Product Description

Model NO.: Many Types

Material: Tungsten Carbide

Style: Universal Tool

Cutting Process: Cutting

Turning Tools Type: Circular Cutting Tool Surface

Milling Cutter Type: Milling

Quality: Good Performance and Stable Quality

Trademark: ZZ HARDMETAL

Origin: China

Type: Cutter

Standards: Pmk

Structure: Integral

Work Type: Cut Off

Boring Tool Type: Fine Boring Tool

Usage: Cutting

Feature: Wear Resistant

Specification: many

HS Code: 82090010

ZZ HARDMETAL established in 2007, as a big and famous manufacturer in Zhuzhou,China. We produce various kinds of tungsten carbide products,including Carbide Inserts, Carbide Rods ,carbide tips, Carbide Strips, Carbide Plates,Carbide Wire Drawing Dies, carbide Cold Forging Dies, carbide punches, woodworking tools,mining drill bits,carbide buttons,etc.

Our customers spread all over 50 countries. We provide our customers the carbide products with good quality,competitive price,fast delivery time and reliable after sale service. To your reference, you can check more items from our website: www.zzhardmetal.cn

We supply all kinds of tungsten carbide discs, mainly used for paper, tobacco, rubber, plywood, hardwood, PCB, PVC, stainless steel, high manganese steel and PCB, PVC electronic circuit boards and and lamp tube, fiber cement board and other materials industry. Grades in: YG6A, YG8A, YG8X, YG8, YG10X, YS2T so on. These products require high precision, no glitches, no indentation phenomenon, so a larger cut of difficulty, To solve this problem, we have static pressing, HIP sintering greatly improve the physical properties of the product, polishing plating, so that when the blade cut, easy to wear and does not stick powder, reducing friction when cutting, greatly improving the accuracy and speed slitting, tool life extended, success for the user to save a lot of manpower and financial resources.

We also recommend suitable grades according to customer demand.

We make according to customer's drawings.

High precision Circular Disc cutter, round-cut blades (high wear / sharp / stainless)

1, Tolerance: High Availability to diameter (± 0.01) * Thickness (± 0.005) * inner diameter (H7) * balance (± 0.005)

2, Hardness: HRC64 ° ~ 66 ° And HRC68 ° ~70 °

3, Features: Cutting Blade requires precision diameter, thickness, straightness, etc. Customized are also welcomed!

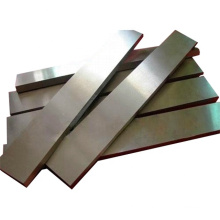

Carbide Discs Description:

Carbide Discs is mainly used for paper, rubber, plywood, hardwood, PCB, PVC, stainless steel, high manganese steel and PCB, PVC electronic circuit boards and other materials industry.

Materials: YG6A, YG8A, YG8X, YG8, YG10X, YS2T and so on.

These products require high precision, no glitches, maximum abrasion resistance. We are using HIP sintered and fine grinding, polishing plating to reduce frictions when cutting, improved the accuracy and speed slitting greatly, tool life extended!

Grades:

YG8 and YS2T are widely used for making carbide cutting disc. But other size can be offered by your requirement.

Grade properties:

YG8: High strength in use, impact and shock resistance higher than YG6, but wear resistance and cutting speed comparatively lower. Roughing of cast irons, non-ferrors metals and their alloys as well as non metallic materials at low cutting speed.

YS2T: Fine grade alloy, with high wear resistance, high bending strength, high resistance to bonding, high thermal strength. Machining of refractory alloys, stainless steel and high manganese steel, etc.

ZZ HARDMETAL provides the followings as a guide to satisfy you:

Availability

Durability

Rust resistance

Cutting process

Costs

Edge geometry

Wear resistance

Ways to identify good carbide disc

1. Sound checking: Before installing the blade, hang the blade with fingers. Gently knock with a wooden hammer, listen to sounds, it is cracked if muddy sound, prohibited to use if cracked, in order to avoid accidents!

2. Running speed: Make sure the cutting speed is in or below 4800 rev/min.

3. Blade install: When installing, rotating shaft and blade center requires accurate alignment of the blade, clean the mechanical mounting surfaces, no cutting material, dust or other debris to be left on blades.

4. Install protective devices: You must install the protective cover (blades should baffle around the studio, steel, rubber and other protective equipment) before the blade running.

Contact us if you need more details on Carbide Disc. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Carbide Disc with Serration Teeth Tips、Round Cutter with Carbide Tips. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Circular Disc

Premium Related Products

Other Products

Hot Products

DTH Hammer and Button BitsISO Tungsten Carbide End Mills for Cutting (45HRC, 55HRC, 65HRC)Carbide Shims (IWSN 633) with High QualityTungsten Carbide Nozzle with All Kinds of TypesPCD Drawing Dies with High QualityTungsten Cabide Ball and SeatTungsten Carbide Burs with Full Range TypesTungsten Carbide Saw Tips K10 Jx5 for Wood CuttingCarbide Mining Tools with High QualitySolid Carbide Rods Yl10.2 H6 for Endmills ReamersCarbide Bushes with High QualityCarbide Disc Cutters with High QualityTungsten Carbide Bars Plates Strips K10 K20 P30Ceramic Tile Cutter in High QualityTungsten Carbide Graver with High QualityCarbide PCBN Inserts with High Quality