Tungsten Carbide Drilling Bits

Basic Info

Model No.: Yg6X Yg3X. Yg8C YL10.2

Product Description

Model NO.: Yg6X Yg3X. Yg8C YL10.2

Certification: BIN

Type: Gun Drill Bit

Use: Metal Drilling

Specification: tungsten carbide

Customized: Customized

Length: Jobber-length

Material: Tungsten Carbide

Trademark: ZZHARDMETAL

Origin: Zhuzhou

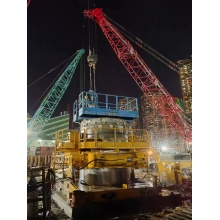

ZZ HARDMETAL -DRILL BRANCH is a member of Chinese Drill Steel & Drill Tools Association.We are doing continuous

technical communication with the laboratories focusing on mining, drilling and tunneling of Chinese famous universities, such as the Drilling Research Laboratory of China University of Geosciences and the Institute of Forming Technology & equipment of Shanghai Jiao Tong University. In the meantime, we closely cooperate with the professional research institutions, Changsha Institute of Mining Research and China Coal Technology & engineering group Shanghai Research Institute.

We own the specialized export company - Zhuzhou ZZ Import and Export Co., Ltd. Our products are exported to USA, Europe, etc. and got trust from our customers. Along with our company growth, we hope to build business with more company abroad.

Classification and characteristics of the alloy teeth

Alloy gear teeth are generally divided into spherical, conical teeth, tooth-shaped shells of three.

Spherical tooth bending, compression is high, toothy low height, toothy part bulky, good wear resistance.

More suitable for drilling in hard, abrasive formations strong. Slow drilling, abrasion best.

Conical teeth bending, compression lowest toothy high altitude. Toothy part of the small, poor wear resistance.

Suitable for drilling soft rock, no fractured rock, drilling faster. Wrong choice could lead alloy tooth fracture, broken, do not wear the situation seriously affect product life and field use.

Bomb-shaped tooth bending, compressive strength is moderate. Toothy high altitude, toothy larger portion size, moderate wear, abrasion resistance is poor.

Features:

Made from top quality steel and tungsten carbide as same as internationally well-known brand

Apply "hot-insertion" processing procedure to insert the buttons as same as internationally well-known brand

Optimized designs improve the drilling speed

Automatic production line ensure the quality stability

Military grade requirements of heat-treatment guarantee durability of the bits.

Thread bit:

Hole Diameter: 35-105mm

Rod length: 1800-6000

Rod diameter: H32,D32,D38

Thread: H25,R32,R35,R38

Material of bit: All-steel, wear-resistant coating, alloy plate,button

Button Bits technical advantages:

1, carbide button with 6% CO, HIP sintered alloy hardness greater than or equal HRA90.5, flexural strength greater than or equal 2600Mpa. The wear resistance and strength of the alloy to achieve a good fit.

2, optional 4340 steel, heat treatment, strength of 1200Mpa, hardness HRC42-45. Ensure Teether effect of the product.

3, cold forming steel body, tapered bore, shape once forging, metal flow lines to ensure the continuity of the steel body stable. Maximum product quality assurance.

4, inlaid with gold teeth blind holes and water holes, heat treatment after machining center using a molding process to ensure consistency and efficiency of perforations.

5, using hot mounting process to ensure Teether effect of the product.

Chisel bit:

Bit Type: Chisel Bits-A,B,C,D,E,F,G

Diameter:34-46mm =(D)

Taper size: 4.8,6,7,11,12

Bottom Hole:22/25mm(d)

Bit Body:Short and Long skirt(H)

Water Hole:2

Advantages of taper chisel bits: cheap in price and the Assorted taper drill rods and rock drills, easy to carry and adequate for various construction conditions. Matched with taper drill rods, the taper chisel bits are widely used in drilling holes with depth less than 5 meters and diameter ranged in 32-46 mm by light-duty rock drill.

Each of rock drill bit is produced in different sizes and designs in order to optimize their application to a broader scope of rock drilling conditions and correspond to different job requirements.

Thread button bit:

Diameter :40 mm -200 mm (D)

Bit Type: Button Bit, Cross Bit

Button Type: Hemispherical, Ballistic, Conical

Thread: R32, R38, T38, T45, T51, T60, ST58(T)

Bit Body: Standard

Bit Face: Flat, Concave, Convex

Taper button bit:

Buttons:3~9

Button Type:Hemispherical, Ballistic, Conical

Diameter :30mm-50mm

Taper:4.8,6,7,11,12°

Bottom Hole:22/25mm,

Bit Body: Short skirt and Long skirt (H)

Water Hole: 2~3

Button bits has higher technology, much longer primary grinding time and higher drilling efficiency while comparing with taper chisel bits and taper cross bits, so that the button bit is popular among the users.

According to the tungsten carbide insert, button bits can be divided into the types of hemispherical button, conical button and parabolic button, etc.

Button bits with hemispherical button is for high bearing capacity and abrasive resistance while conical button and parabolic button are for high drilling speed and low abrasive resistance.

When drilling, adjust the parameters of impulse and rotary with the standards of no jamming, high drilling speed and no bend of tapered drill rods.

Contact us if you need more details on Drilling Bits. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Drilling Bits、Drilling Bits. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Drilling Bits&Mining Bits

Premium Related Products

Other Products

Hot Products

DTH Hammer and Button BitsISO Tungsten Carbide End Mills for Cutting (45HRC, 55HRC, 65HRC)Carbide Shims (IWSN 633) with High QualityTungsten Carbide Nozzle with All Kinds of TypesPCD Drawing Dies with High QualityTungsten Cabide Ball and SeatTungsten Carbide Burs with Full Range TypesTungsten Carbide Saw Tips K10 Jx5 for Wood CuttingCarbide Mining Tools with High QualitySolid Carbide Rods Yl10.2 H6 for Endmills ReamersCarbide Bushes with High QualityCarbide Disc Cutters with High QualityTungsten Carbide Bars Plates Strips K10 K20 P30Ceramic Tile Cutter in High QualityTungsten Carbide Graver with High QualityCarbide PCBN Inserts with High Quality