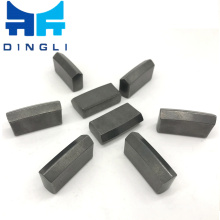

Tungsten Carbide Cold Nibs Pellets

Basic Info

Model No.: Different types

Product Description

Model NO.: Different types Manufacturing Arts: Welding Brand: Zz Hardmetal Types: Different ISO Types Advantages-2: Height/Diamater> 4 Are Availabled Advantages-4: Various of Types and Grades Samples: Avaiable Origin: Zhuzou Kind: Angle Milling Machine Usage: Stone Cutting Specification: Produce Based on Drawing From Clients. Advantages-1: Tungsten Carbide Dies Core for Mould Advantages-3: CIP Pressed Hip Sintered Advantages-5: High Quality, The Best Price Trademark: ZZ HARDMETAL Zhuzhou ZZ Hardmetal, A professional Chinese manufacturer of tungsten carbide products such as inserts, Indexable Inserts Shims, Drilling Bits, drawing dies, Cold Forging Dies, carbide bars, Carbide Rods, Carbide Balls, Carbide Burrs, etc.

We manufacture carbide cold forging dies for many kinds of applications, such as for metal powder and nonmetal poeder, for steel tubes and rods, for wear resistant or impact resistant application, for stainless bolt header dies and rollers, etc.

For tungsten carbide cold forging dies Carbide Zhuzhou cemented carbide products, carbide forming dies.

Our Promise is:

! ! ! ! NO porosity, NO crack, NO quality problem! ! ! ! !

! ! ! ! Any problme caused by us, we compensate you! ! ! !

We can produce many dimensions of tungsten carbide cold heading dies / punch dies / forging dies / tungsten carbide moulds / drawing dies / threading dies

Note 1: We have various different moulds for different dimensions of tungsten carbide cold forging heading dies/ carbide punch dies.

Note 2: We can supply the cold forging dies according to the drawing provided by customers.

3. Packing of our tungsten carbide cold heading dies / punches dies / forging dies / tungsten carbide moulds / drawing dies / threading dies

A. First wrapped with paper

B. Second into paper boxes

C. Last into paper cartons or wooden casese, each 20 to 30 kgs

4. Our aim:

Union, trust, advancement!

To carry out work basing on the true reality principle, to strive to improve customers' satisfaction!

5. If you are interested in us, please note:

1. The grade (if don't know grade, tell me the application, we will choose the grade for you)

2. Quantity (pieces or kgs).

3. Loading port (FOB or CIF).

4. Our payment terms: 10%-30% deposit and the balance against shipment. O/A, L/C, WEST UNION is accepted.

Contact us if you need more details on Tungsten Carbide. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Carbide Cold Forging Dies、Carbide Punching Dies. If these products fail to match your need, please contact us and we would like to provide relevant information.

We manufacture carbide cold forging dies for many kinds of applications, such as for metal powder and nonmetal poeder, for steel tubes and rods, for wear resistant or impact resistant application, for stainless bolt header dies and rollers, etc.

For tungsten carbide cold forging dies Carbide Zhuzhou cemented carbide products, carbide forming dies.

Our Promise is:

! ! ! ! NO porosity, NO crack, NO quality problem! ! ! ! !

! ! ! ! Any problme caused by us, we compensate you! ! ! !

We can produce many dimensions of tungsten carbide cold heading dies / punch dies / forging dies / tungsten carbide moulds / drawing dies / threading dies

Note 1: We have various different moulds for different dimensions of tungsten carbide cold forging heading dies/ carbide punch dies.

Note 2: We can supply the cold forging dies according to the drawing provided by customers.

3. Packing of our tungsten carbide cold heading dies / punches dies / forging dies / tungsten carbide moulds / drawing dies / threading dies

A. First wrapped with paper

B. Second into paper boxes

C. Last into paper cartons or wooden casese, each 20 to 30 kgs

4. Our aim:

Union, trust, advancement!

To carry out work basing on the true reality principle, to strive to improve customers' satisfaction!

5. If you are interested in us, please note:

1. The grade (if don't know grade, tell me the application, we will choose the grade for you)

2. Quantity (pieces or kgs).

3. Loading port (FOB or CIF).

4. Our payment terms: 10%-30% deposit and the balance against shipment. O/A, L/C, WEST UNION is accepted.

| Grade | Density(g/cm3) | T. R. S(MPA) | Hardness(HRA) | Performance & application recommended |

| YG11 | 14.4 | 2600 | 88.5 | Forming or stamping dies for metal powders and nonmetal powders. |

| YG15 | 14.0 | 2800 | 87.5 | For fabricating drawing dies of steel tubes and rods under High compressibility ratio; punching, stamping, and forging tools under large stress. |

| YG20 | 13.5 | 3200 | 85.5 | For fabricating of stamping dies for watch parts, spring plates of musical instruments, battery jars, small sized steel balls, screws, screw caps. |

| YG16C | 13.9 | 2900 | 85.5 | Impact resistance forging dies. |

| YG18C | 13.7 | 3100 | 84.5 | Impact resistance forging dies, hot-press forging dies and rollers. |

| YG20C | 13.5 | 3300 | 83.5 | Dies for wear resistant or impact resistant application. |

| YG22C | 13.3 | 3500 | 83.0 | Nut forming dies and high impact resistance forging dies. |

| YG22C | 13.3 | 3500 | 83.0 | Nut forming dies and high impact resistance forging dies. |

Contact us if you need more details on Tungsten Carbide. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Carbide Cold Forging Dies、Carbide Punching Dies. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Cold Stamping Dies

Premium Related Products

Other Products

Hot Products

DTH Hammer and Button BitsISO Tungsten Carbide End Mills for Cutting (45HRC, 55HRC, 65HRC)Carbide Shims (IWSN 633) with High QualityTungsten Carbide Nozzle with All Kinds of TypesPCD Drawing Dies with High QualityTungsten Cabide Ball and SeatTungsten Carbide Burs with Full Range TypesTungsten Carbide Saw Tips K10 Jx5 for Wood CuttingCarbide Mining Tools with High QualitySolid Carbide Rods Yl10.2 H6 for Endmills ReamersCarbide Bushes with High QualityCarbide Disc Cutters with High QualityTungsten Carbide Bars Plates Strips K10 K20 P30Ceramic Tile Cutter in High QualityTungsten Carbide Graver with High QualityCarbide PCBN Inserts with High Quality