Tungsten Carbide Balls and Valve Seats

Basic Info

Model No.: carbide balls and seats 002

Product Description

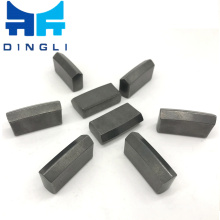

Model NO.: Carbide Balls And Seats 002 Surface Treatment: Grinding Chemical Composition: Wc, Co etc Sample: Available Trademark: ZZ HARDMETAL Certification: ISO9001:2008 Certificate Material: Tungsten Carbide Service: OEM & ODM Processing Type: Rolling Type Zhuzhou ZZ Hardmetal was established in the hometown of hard metal of China - Zhuzhou City in Hunan Province. We are a professional Chinese manufacturer of tungsten carbide products such as inserts, Indexable Inserts Shims, Drilling Bits, drawing dies, Cold Forging Dies, carbide bars, Carbide Rods, Carbide Balls, Carbide Burrs, Carbide Rings, etc.

1.100% virgin raw material

2. Well hardness & resistance

3. Many sizes & types available

4. ISO9001: 2008 certificate

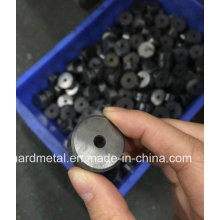

Percision machined carbide balls and valve seats

1. High strength, hign wear resistance, high percision, good temperature resistance and good corrosion resistance.

2. Mainly used for the sealing of valves of oil pumps in petroleum industry`s containing wells, viscous oil wells, sea oil wells and high pressure sulfur resistant oil wells, etc.

3. Balls and seats are used with compatiable cemented carbide valve seats.

4. The finished surface, tolerance standard have reached the standards of the machine industry: G5, G10, G16, G40 and G100 of JB/T 9145-1999.

5. Precision machined cemented carbide balls of other grades and specifications are also available based on customers` demands.

6. Compatiable high precision valve seats can also be made.

Carbide manufacturing process

The production process for various grades of cemented carbide is basically the same, i. e. Prepare powder burden powder mixing-pressing-sintering-post machining. Only some minor process parameter adjustments need to be done occasionally.

In the course of over 70 years of development and as basic theoretical research goes deeper internationally, carbide industry's equipment and technologies improved significantly. New technologies and equipment emerged in western countries in 1970s have become more and more popular in China's carbide manufacturing industry and are driving the development of carbide industry in China.

Powder mixing operation: Tumbling ball mill is gradually changing to blending ball mill, and roller screen granulation is gradually changing to spray granulation.

Pressing operation: As pressing machines become more precise, precision pressing has become the trend. Other new ways for forming carbide products are also emerged, such as vacuum extrusion and cold ISO-static press, etc.

Sintering operation: The earliest method was to use hydrogen sintering furnace, and then, vacuum sintering and hot ISO-static press furnace were adopted. The most revolutionary change was the emergence of sinter-HIP furnace, which made it possible to produce 100% dense carbide products.

Carbide Grades:

Many carbide grades can meet your requirements for precision machined cemented carbide balls in their good precision, good wear resistance and good corrosion resistance

ZZ HARDMETAL

Shine Lei

Mob: +86 13762227700

Contact us if you need more details on Tungsten Carbide Bearing Balls. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Tungsten Carbide Valve Seat、Tungsten Carbide Seat. If these products fail to match your need, please contact us and we would like to provide relevant information.

1.100% virgin raw material

2. Well hardness & resistance

3. Many sizes & types available

4. ISO9001: 2008 certificate

Percision machined carbide balls and valve seats

1. High strength, hign wear resistance, high percision, good temperature resistance and good corrosion resistance.

2. Mainly used for the sealing of valves of oil pumps in petroleum industry`s containing wells, viscous oil wells, sea oil wells and high pressure sulfur resistant oil wells, etc.

3. Balls and seats are used with compatiable cemented carbide valve seats.

4. The finished surface, tolerance standard have reached the standards of the machine industry: G5, G10, G16, G40 and G100 of JB/T 9145-1999.

5. Precision machined cemented carbide balls of other grades and specifications are also available based on customers` demands.

6. Compatiable high precision valve seats can also be made.

Carbide manufacturing process

The production process for various grades of cemented carbide is basically the same, i. e. Prepare powder burden powder mixing-pressing-sintering-post machining. Only some minor process parameter adjustments need to be done occasionally.

In the course of over 70 years of development and as basic theoretical research goes deeper internationally, carbide industry's equipment and technologies improved significantly. New technologies and equipment emerged in western countries in 1970s have become more and more popular in China's carbide manufacturing industry and are driving the development of carbide industry in China.

Powder mixing operation: Tumbling ball mill is gradually changing to blending ball mill, and roller screen granulation is gradually changing to spray granulation.

Pressing operation: As pressing machines become more precise, precision pressing has become the trend. Other new ways for forming carbide products are also emerged, such as vacuum extrusion and cold ISO-static press, etc.

Sintering operation: The earliest method was to use hydrogen sintering furnace, and then, vacuum sintering and hot ISO-static press furnace were adopted. The most revolutionary change was the emergence of sinter-HIP furnace, which made it possible to produce 100% dense carbide products.

Carbide Grades:

Many carbide grades can meet your requirements for precision machined cemented carbide balls in their good precision, good wear resistance and good corrosion resistance

ZZ HARDMETAL

Shine Lei

Mob: +86 13762227700

| Dia (D) | Inch | 3/4 | 7/8 | 15/16 | 1 | 11/8 | 13/16 |

| mm | 19.050 | 22.225 | 23.813 | 25.400 | 28.575 | 30.163 | |

| Inch | 11/4 | 13/8 | 11/2 | 15/8 | 1 11/16 | 1 3/4 | |

| mm | 31.750 | 34.925 | 38.100 | 41.275 | 42.863 | 44.450 | |

| Inch | 2 | 11/4 | 2 1/2 | ||||

| mm | 50.000 | 50.800 | 57.150 | 60.000 | 63.500 |

Contact us if you need more details on Tungsten Carbide Bearing Balls. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Tungsten Carbide Valve Seat、Tungsten Carbide Seat. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Carbide Balls And Seats

Premium Related Products

Other Products

Hot Products

DTH Hammer and Button BitsISO Tungsten Carbide End Mills for Cutting (45HRC, 55HRC, 65HRC)Carbide Shims (IWSN 633) with High QualityTungsten Carbide Nozzle with All Kinds of TypesPCD Drawing Dies with High QualityTungsten Cabide Ball and SeatTungsten Carbide Burs with Full Range TypesTungsten Carbide Saw Tips K10 Jx5 for Wood CuttingCarbide Mining Tools with High QualitySolid Carbide Rods Yl10.2 H6 for Endmills ReamersCarbide Bushes with High QualityCarbide Disc Cutters with High QualityTungsten Carbide Bars Plates Strips K10 K20 P30Ceramic Tile Cutter in High QualityTungsten Carbide Graver with High QualityCarbide PCBN Inserts with High Quality