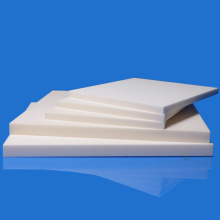

wear corrosion resistant alumina insulator spacer ring

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

|---|---|

| Terms of Trade: | FOB |

| Min. Order: | 1 Piece/Pieces |

| Delivery Time: | 15 Days |

| Packaging: | Customized |

|---|---|

| Brand: | Hard |

| Transportation: | Ocean,Land,Air |

| Place of Origin: | Guangdong,China |

| Supply Ability: | 1,000,000 pcs/Month |

| Certificate: | SGS |

| Port: | Shenzhen |

Basic Info

Model No.: Al2O3 339

Click on the follow link to find out more information: https://www.hardcm.com/alumina-ceramic-shaft/

Company Info

- Company Name: Dongguan Haikun New Material Co., Ltd.

- Representative: ZHOU SHENGBIN

- Product/Service: Alumina Ceramics , Zirconia Ceramics , Silicon Nitride Ceramics , Macor Ceramic , Aluminum Nitride Ceramic , Other Ceramic Materials

- Capital (Million US $): US$500,000

- Year Established: 2007

- Total Annual Sales Volume (Million US $): US$2.5 Million - US$5 Million

- Export Percentage: 81% - 90%

- Total Annual Purchase Volume (Million US $): US$1 Million - US$2.5 Million

- No. of Production Lines: 5

- No. of R&D Staff: 5 -10 People

- No. of QC Staff: 5 -10 People

- OEM Services Provided: YES

- Factory Size (Sq.meters): 1,000-3,000 square meters

- Factory Location: 5F, 3BLD, SHIDAIZHIHUI, 159Luwusanlian Rd., Changping, Dongguan, China 523587

- Contact Person: Mr. Watson Lin

- Tel: 86-0769-81182989

Email to this supplier

Premium Related Products

Other Products

Hot Products

DTH Hammer and Button BitsISO Tungsten Carbide End Mills for Cutting (45HRC, 55HRC, 65HRC)Carbide Shims (IWSN 633) with High QualityTungsten Carbide Nozzle with All Kinds of TypesPCD Drawing Dies with High QualityTungsten Cabide Ball and SeatTungsten Carbide Burs with Full Range TypesTungsten Carbide Saw Tips K10 Jx5 for Wood CuttingCarbide Mining Tools with High QualitySolid Carbide Rods Yl10.2 H6 for Endmills ReamersCarbide Bushes with High QualityCarbide Disc Cutters with High QualityTungsten Carbide Bars Plates Strips K10 K20 P30Ceramic Tile Cutter in High QualityTungsten Carbide Graver with High QualityCarbide PCBN Inserts with High Quality